Metal powder injection molding (MIM) can directly form small parts with high precision and complicated shape parts, and it has a wide range of materials. Since its introduction to China in 1970s, it has gained rapid development in all fields of life.

Metal powder injection molding in China earlier used in the production of ordnance, which mainly includes guns, shells and other parts. Gun parts shape and structure are more complex. Due to gun parts application of special environment and has a certain risk, it determines the they must have very high quality, including mechanical properties, density, accuracy and so on.

Conventional gun parts are generally made of forged blanks, which can be machined to higher quality. However, the utilization rate of machined materials is low, especially for structural parts and metal shells of pistols. Of the utilization of only 15% -20%, most of the materials are cut off. And for small gun parts (plate machine, card stalls, etc.), high-strength materials (carbon steel, etc.) production are difficult to make, low efficiency, and not economy.

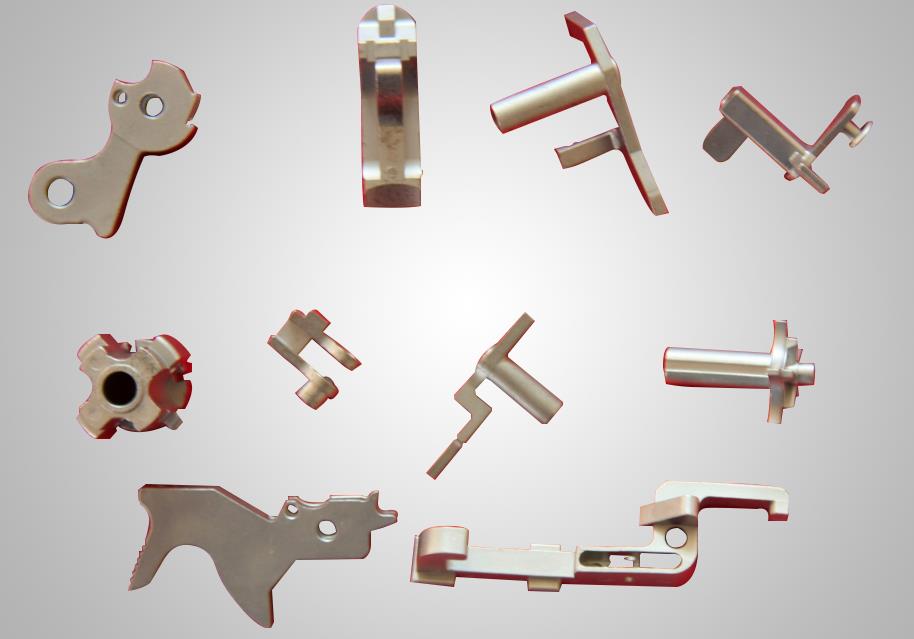

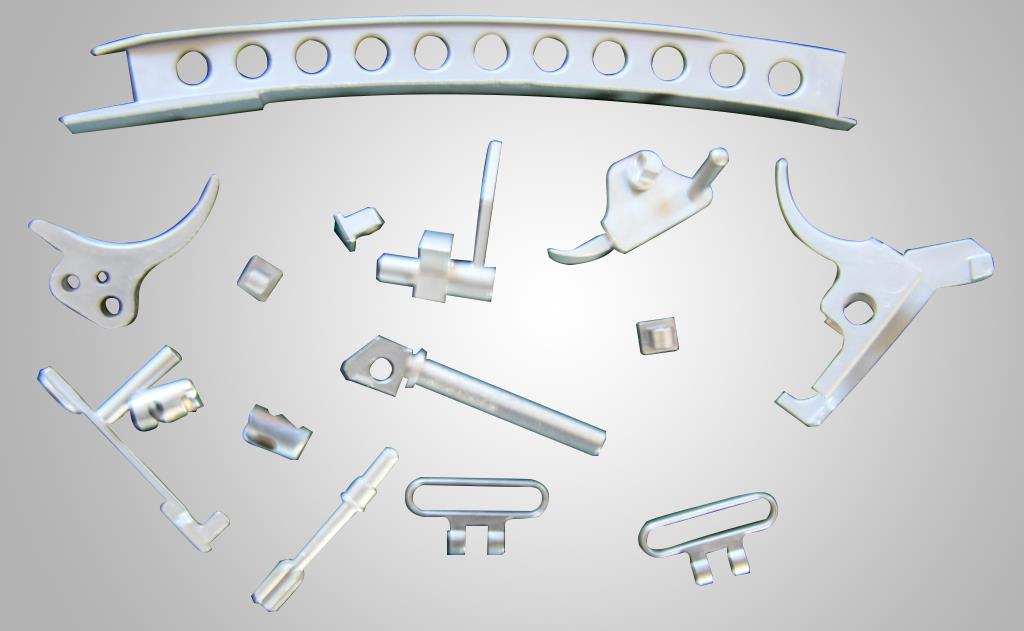

MIM can form various parts of complex shapes, and overcome the low utilization of machining materials problem. So it can save a lot of metal materials, greatly reduce the processing costs. Because MIM has many advantages, people began to use this process to produce a variety of gun parts, such as gauge, resistance iron body, board machine, card booth, safety rods etc.. With the development of metal powder injection, MIM parts in the composition of guns occupy an increasing proportion.

At present, as to the rifle, in addition to gun body, gun stock and other large parts, the rest of the metal parts are mostly made by metal injection molding. In a pistol, bolt, trigger, shell also used MIM to make. This technology is suitable for a wide range of materials, can produce a variety of metal materials, gun parts, to meet people's application of a variety of firearms needs.

In addition, parts made by this technology have characteristics of high quality consistency, high density, and less post-machining. Most parts without CNC machining can meet the required accuracy requirements, so that MIM parts in gun parts occupy a considerable proportion.

At present, few factories use MIM technology to produce gun parts. We look forward to more enterprises, more products can be used in firearms, weapons industry.

Pistol Rifle MIM Spare |  Gun customed metal parts |